Extending battery life through precision diagnostics and module-level reconditioning

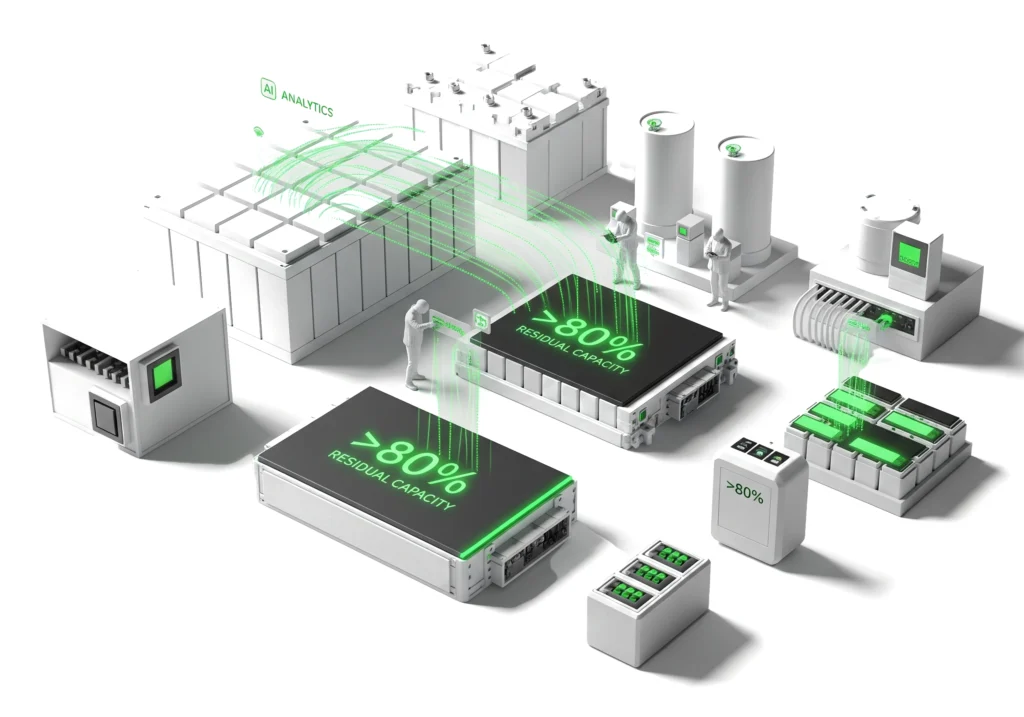

Batteries should never retire early. At MDK Sustech, our battery refurbishment programme combines AI-driven health analytics, module-level reconditioning and factory-grade testing to breathe new life into EV, industrial and consumer packs.

The result: >80 % residual capacity backed by a 5-year performance warranty, slashing total cost of ownership up to 45 % while keeping critical metals in productive use for an extra 5–8 years.

AI-powered battery health mapping

Our robotic test benches run electrochemical impedance spectroscopy (EIS), incremental capacity analysis (ICA) and self-learning ML models to grade every cell within 90 seconds. Data feeds a cloud-based dashboard that predicts remaining useful life (RUL), residual capacity and optimal second-life application—enabling buy-back pricing 30 % above market scrap value.

Precision repair without full teardown

Technicians open packs in ISO 14644-7 clean cells, swap degraded cells with matched-impedance replacements, flash new BMS firmware for balanced charging and install phase-change thermal pads. Each module undergoes dynamic cycling tests at 1 C/1 C for 50 cycles to validate capacity retention ≥80 % and internal resistance ≤110 % of spec.

From traction to stationary storage

Refurbished modules receive IP67 aluminum enclosures, active cooling and CAN-bus communication for seamless integration into BESS containers, telecom towers and commercial UPS racks. UL 1974 compliance and IEC 62619 safety certification open doors to global markets, delivering 2–3× residual value compared with raw material recovery alone.

5-year coverage you can bank on

Every refurbished battery ships with a 5-year pro-rata warranty and IoT telemetry that streams temperature, voltage and cycle-count data to our NOC. Machine-learning anomaly detection triggers predictive maintenance alerts before faults occur, ensuring uptime >99 % and protecting ROI for operators and financiers.

Leasing, buy-back and revenue-share options

Choose pay-per-cycle leasing, guaranteed buy-back or revenue-share models tailored to cash-flow needs. Our dashboard quantifies residual value, carbon credits and avoided mining costs, enabling CFOs to treat refurbished packs as circular assets on the balance sheet.

Discover hidden value in your end-of-life packs.

Send us your battery data sheet or schedule an on-site audit. Within 48 hours you’ll receive a refurbishment feasibility report with ROI projections and warranty terms.

Book a capacity audit today

Battery Recycling News

Industry Reports

Sustainable Tech Insights

Case Studies

Privacy Policy

Terms & Conditions

© 2025 MDK Sustech All Copyrights Reserved