End-to-end strategies that keep critical metals in perpetual motion

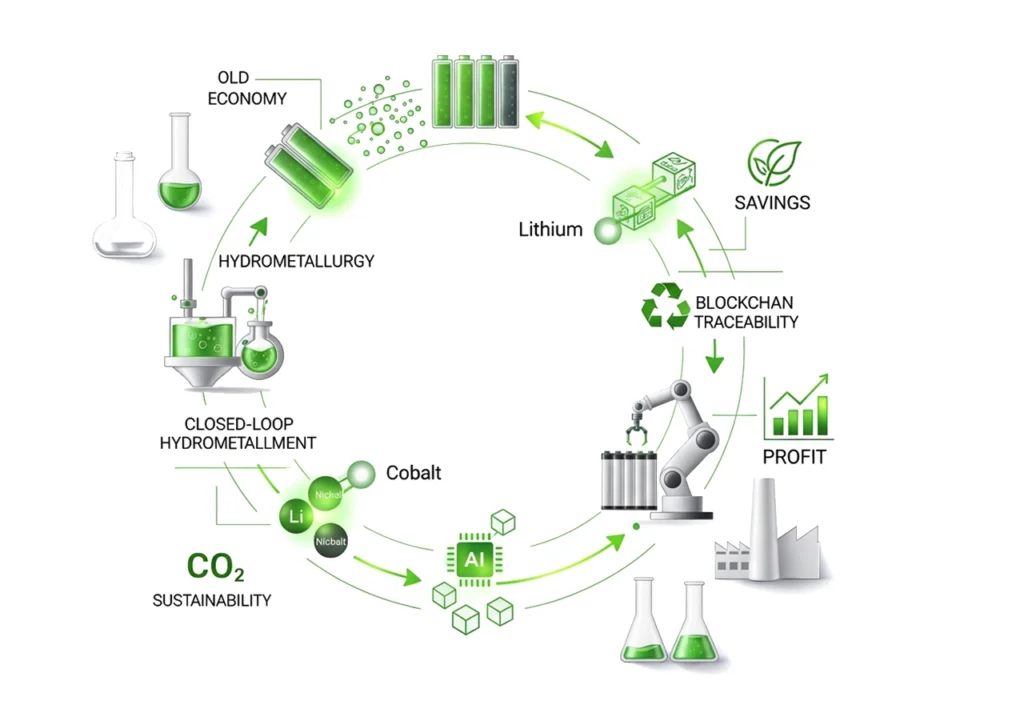

At MDK Sustech, we don’t just recycle batteries—we re-architect the entire material journey. Our circular-economy solutions transform yesterday’s cells into tomorrow’s feedstock, eliminating the need for virgin mining while delivering measurable CO₂ savings of up to 70 % and new profit channels for OEMs, fleet operators and recyclers alike. By integrating closed-loop hydrometallurgy, AI-driven refurbishment and blockchain traceability, we ensure that every gram of lithium, nickel and cobalt circulates indefinitely, powering a resilient, low-carbon economy.

Design products and processes for infinite reuse

Our regenerative design framework starts upstream. Using life-cycle assessment (LCA) software and cradle-to-cradle principles, we audit bill-of-materials, joint geometries and polymer blends to guarantee >95 % disassembly in under 15 minutes. We specify single-polymer casings, snap-fit interconnects and standardised cell footprints that survive multiple remanufacturing cycles. The result: batteries that re-enter production lines instead of landfills, cutting virgin material demand by up to 70 % and engineering cost-effective reverse logistics before the first cell rolls off the assembly line.

From spent battery to new cathode without leaving the loop

Our closed-loop hydrometallurgical circuit treats shredded black mass in a cascade of solvent-free leaching, selective precipitation and crystallisation steps. Lithium, nickel and cobalt are isolated at 99.95 % purity, then re-precipitated as carbonate, sulfate or hydroxide ready for immediate synthesis of fresh CAM (cathode active material). Because microstructure integrity is preserved, recovered metals perform identically to virgin feedstock, enabling direct refeed into gigafactory precursor lines and slashing embedded CO₂ by >60 % compared with mined sources.

Second-life batteries, first-class performance

Inside regional reuse & refurbishment hubs, automated test rigs run EIS spectroscopy and capacity fade modelling to grade every cell. Healthy modules receive new BMS firmware, thermal barriers and IP67 enclosures before redeployment in grid-scale storage, UPS systems or micro-grids. Each refurbished unit ships with a 5-year performance warranty, generating 2–3× residual value versus raw material recovery alone while deferring recycling by 5–8 years—a textbook cascade use that maximises resource productivity.

Blockchain traceability from cradle to reincarnation

Our blockchain-based digital passports assign every battery a unique NFT-style token containing BOM data, CO₂ footprint, cycle count and health metrics. Smart contracts automatically trigger residual-value payouts at transfer points, while recyclers receive granular dismantling instructions. The open API integrates with ERP, ESG reporting and EU Battery Passport requirements—turning transparency into a competitive edge.

Monetise circularity with data-driven business models

Our economics-as-a-service platform simulates capex, opex and revenue across leasing, buy-back or pay-per-cycle schemes. Clients access real-time NPV, IRR and carbon-savings forecasts for each battery cohort, while our performance-guarantee contracts de-risk adoption. The outcome: circular business models that pay for themselves within 24–36 months and keep resources circulating indefinitely.

Ready to close your loops and open new revenue streams?

Book a 30-minute strategy call with our circular-economy team and receive a bespoke closed-loop blueprint—complete with material-flow maps, financial projections and regulatory alignment—for your battery portfolio.

Get in Touch with Our Experts

Battery Recycling News

Industry Reports

Sustainable Tech Insights

Case Studies

Privacy Policy

Terms & Conditions

© 2025 MDK Sustech All Copyrights Reserved