Zero-Waste, Zero-Carbon Commitment

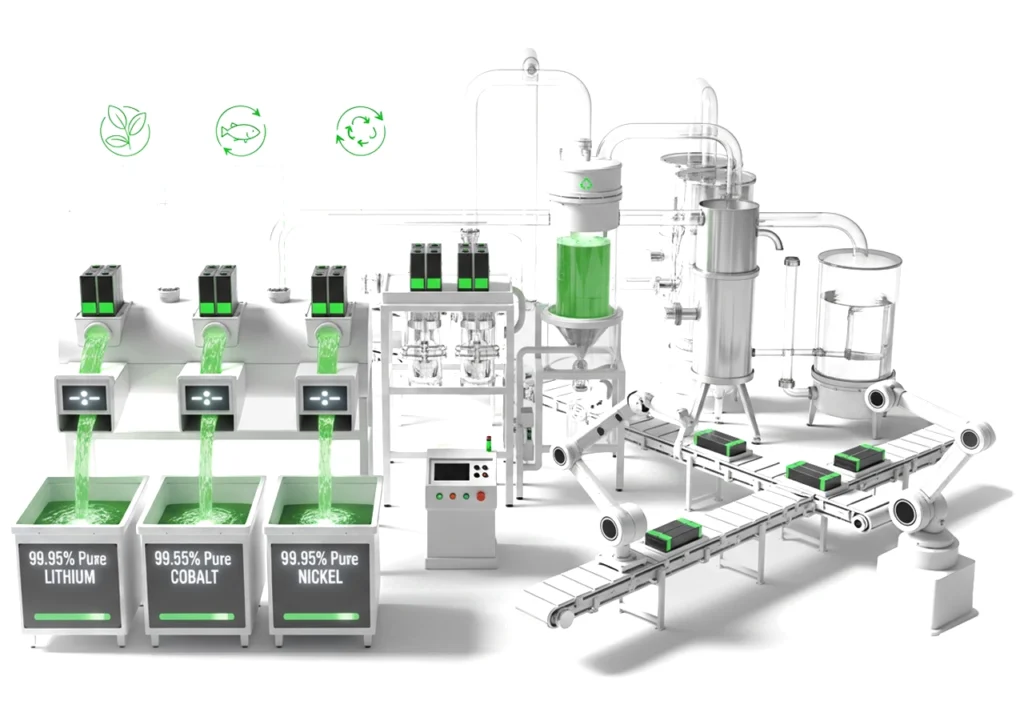

At MDK Sustech, environmental responsibility is not an afterthought—it’s engineered into every step of our battery recycling workflow. From zero-wastewater hydrometallurgy to carbon-neutral logistics, our systems are purpose-built to protect ecosystems while recovering 99.95 %-pure critical metals for reuse in next-generation batteries.

Closed-Loop Water Management

Our zero-wastewater technology treats and recycles every litre of process water on-site. Advanced membrane filtration and selective precipitation capture lithium salts, cobalt residues, and fluorinated compounds, preventing aquatic contamination and lowering freshwater demand by 85 %.

Emission-Free Collection & Delivery

Through electric vehicle fleets, renewable-energy warehouses, and AI-optimized routing, we offset 100 % of transport-related emissions. Clients receive real-time carbon-savings dashboards for ESG reporting and compliance with EU Battery Directive 2023/1542.

65 % Less Energy Than Pyrometallurgy

Our low-temperature, solvent-free hydrometallurgical circuit consumes 65 % less energy than conventional smelting. Heat-exchanger networks and on-site solar arrays further reduce grid draw, cutting scope-2 emissions to near zero.

Safely Eliminate Forever Chemicals

Electro-oxidation cells combined with catalytic reduction break PFAS molecules into harmless fluoride and carbon dioxide. The system exceeds US EPA PFAS Strategic Roadmap targets and produces no hazardous ash, ensuring full cradle-to-grave compliance.

Design-for-Recycling Support

Help OEMs create batteries that are easier to recycle tomorrow.

We provide design-for-recycling audits and material selection guidance to battery manufacturers. By specifying snap-fit casings, single-polymer modules, and standardized cell formats, we extend product life and simplify end-of-life recovery—closing the loop before the battery is even built.

Tailored Environmental Compliance

Achieve site-specific sustainability targets.

Every facility has unique footprints. Our engineers design tailored environmental solutions—from on-site solar micro-grids to closed-loop cooling—that meet local regulations and your corporate net-zero roadmap. Whether you require ISO 14001 certification or Science-Based Targets initiative alignment, we deliver measurable results.

Discuss your environmental goals with our specialists.

Ready to cut waste, slash emissions, and lead the green transition? Contact our environmental solutions team today for a bespoke roadmap to zero-impact battery recycling.

Get in Touch with Our Experts

Battery Recycling News

Industry Reports

Sustainable Tech Insights

Case Studies

Privacy Policy

Terms & Conditions

© 2025 MDK Sustech All Copyrights Reserved